Addivant Germany GmbH, Waldkraiburg (ehem. Chemtura Manufacturing Germany GmbH)

- Dust recovery at bag-filling station.

- Dimensioning of supply-air components for ventilation of a container cleaning station.

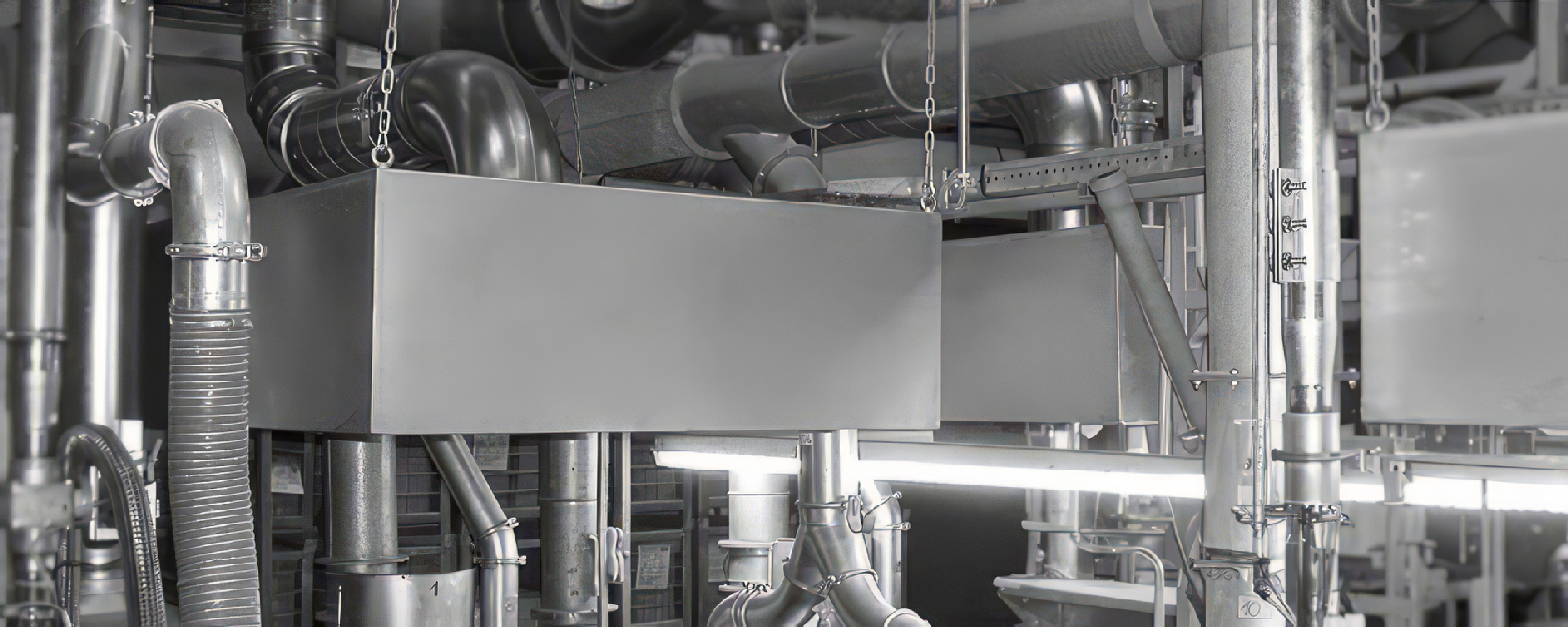

Basell Polyolefine GmbH, Knapsack

- Planning and installation of central dust removal system to cover an entire

manufacturing area.

Bayer MaterialScience AG, Krefeld and Dormagen

- Maintenance of supply and exhaust air systems for several cleanrooms in the domain

of MAKROLON®-filling. - Planning and installation of central dust removal systems in the domain of MAKROLON®-

compounding. - Conversion of complete dust removal system in a production complex.

- Maintenance of central dust recovery system in the domain of MAKROLON®-compounding.

Bayer MaterialScience AG, Guangzhou (China)

- Planning and installation of the central dust recovery system at the Guangzhou plant.

DSM Nutritional Products GmbH

- Dimensioning and installation of a sinter filter system with back-up filter.

Dynea Austria GmbH, Krems (Austria)

- Planning and installation of a filter system and removal of melamine dust

at a BigBag-emptying station. - Dimensioning and delivery of several bunker top filters.

Eckart GmbH, Velden and Wackersdorf

- Planning and installation of dust removal system at diverse silo filling stations.

- Planning and installation of filter system and vapor evacuation an a copper smelting plant.

- Dimensioning and delivery of dust recovery at diverse reactors.

H. C. Starck GmbH, Goslar

- Planning and installation of an automatic separation station

for highly-purified niobium/tantalum. - Dimensioning and delivery of diverse customer-specific recovery elements.

- Dimensioning and delivery of various retort cooling stations.

- Planning and installation of pollutant removal at various production installations.

- Dimensioning and delivery of diverse customer-specific special filter systems.

- Maintenance of various indoor ventilation systems.

Karl Wörwag Lack- und Farbenfabrik GmbH & Co. KG, Stuttgart

- Planning and installation of recovery and filtration of aluminum dust at weighing station.

- Planning and installation of pollutant recovery at extruders.

Konrad Hornschuch AG, Weißbach

- Dimensioning and conversion of bunker top filters at sinter filter systems.

Lanxess Deutschland GmbH, Uerdingen

- Planning and installation of central vacuuming units in iron oxide processing.

- Various planning projects in iron oxide processing.

- Planning and installation of pollutant recovery in iron oxide processing.

- Planning und implementation of pollutant recovery in chrome oxide processing.

- Planning and construction of granulate conveying in chrome oxide processing.

- Planning and installation of central vacuum system in chrome oxide processing.

- Planning and installation von diverse pressure fluctuation filters (EQFILTER).

LEONHARD KURZ Stiftung & Co. KG, Fürth

- Planning of the entire supply and exhaust air installation at the new lacquer mixing

center in Fürth. - Realization of pollutant and exhaust-air recovery at the new lacquer mixing center.

Momentive Performance Materials GmbH, Leverkusen

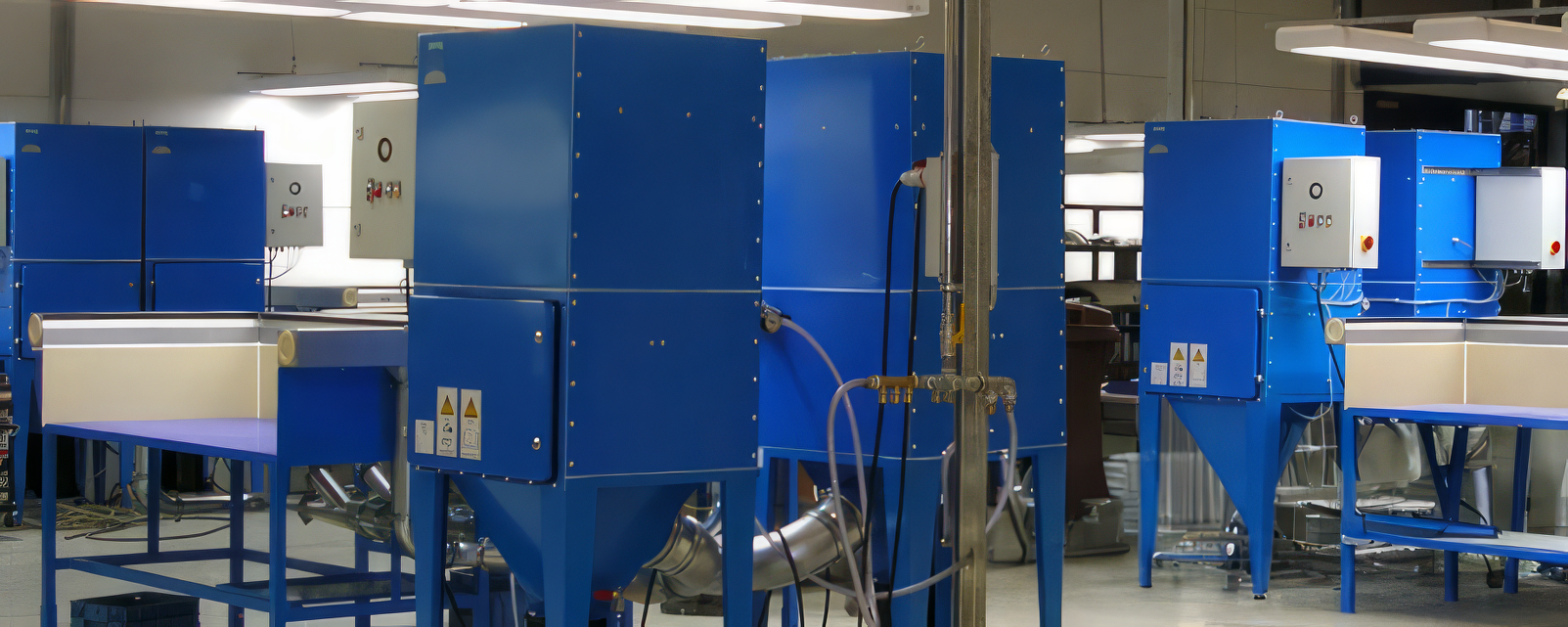

- Planning and installation of dust recovery and filter system at the emptying station

for silicon containers. - Dimensioning and delivery of pollutant recovery and filtration (MOBOX) at a keg-filling station.

PROPHYTA Biologischer Pflanzenschutz GmbH, Wismar (jetzt Bayer CropScience Biologics GmbH)

- Planning and installation of powder dust recovery in a packing room.

- Maintenance of various indoor ventilation systems.

Reckitt Benckiser Deutschland GmbH, Ladenburg

- Planning and installation of various central dust vacuum stations at diverse manufacturing

and packaging units. - Planning and installation of dust recovery and filtration at diverse manufacturing

and packaging units. - Planning and installation of customer-specific vacuum station for packing foils.

Schunk Kohlenstofftechnik GmbH, Heuchelheim

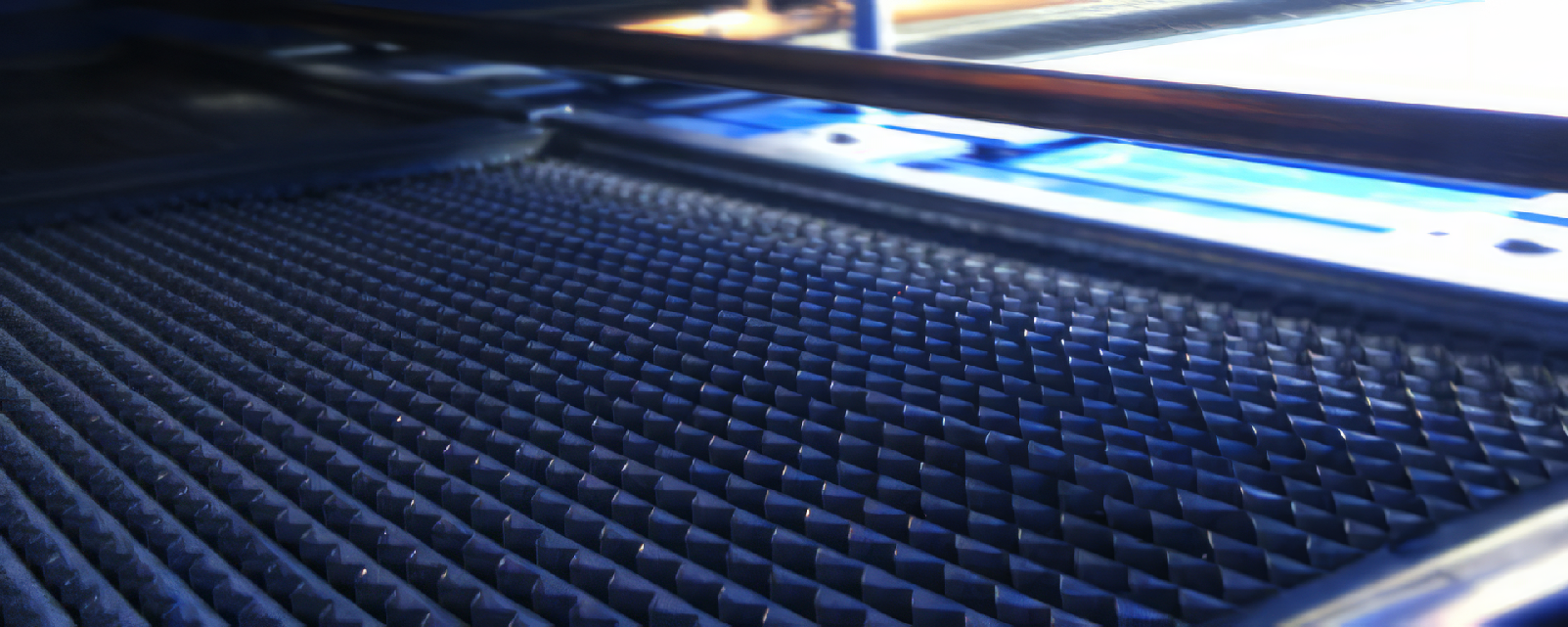

- Planning and installation of solution vapor evacuation systems for manufacture

of carbon fiber reinforced plastic molded parts.

- Planning and installation of dust recovery unit at engraving stations for graphite blocks.

- Planning and installation of a pneumatic graphite dust conveyor.

- Preparing a concept for optimizing dust recovery in a new production area.

- Planning and installation of dust recovery systems in diverse production installations.